This is the second part in our series on inventory models in China's New Retail era. To read part one, focusing on the fixed inventory model, New Retail in Chinese eCommerce: Fixed Inventory ModelWe profile one of the two leading inventory models that has arisen in the innovative logistics environment of the New Retail era.click here.

In 2019, exactly how to manage warehousing logistics and order management has become a hot topic in China’s New Retail space. Brands are using innovative new models to differentiate themselves from competitors. These models optimize both operational efficiency and user experience, and help brands stay ahead of the pack.

Even more so than with traditional retail, the availability of in-store inventory is crucial to New Retail. Requirements are increasing as each offline store takes up its position at the forefront of a brand’s omni-channel strategy.

Most businesses innovating in this space fall into two main models: fixed inventory and mixed inventory. In this article we take a look at the second of these, to see how it works and explore its features and advantages.

Mixed Inventory Model

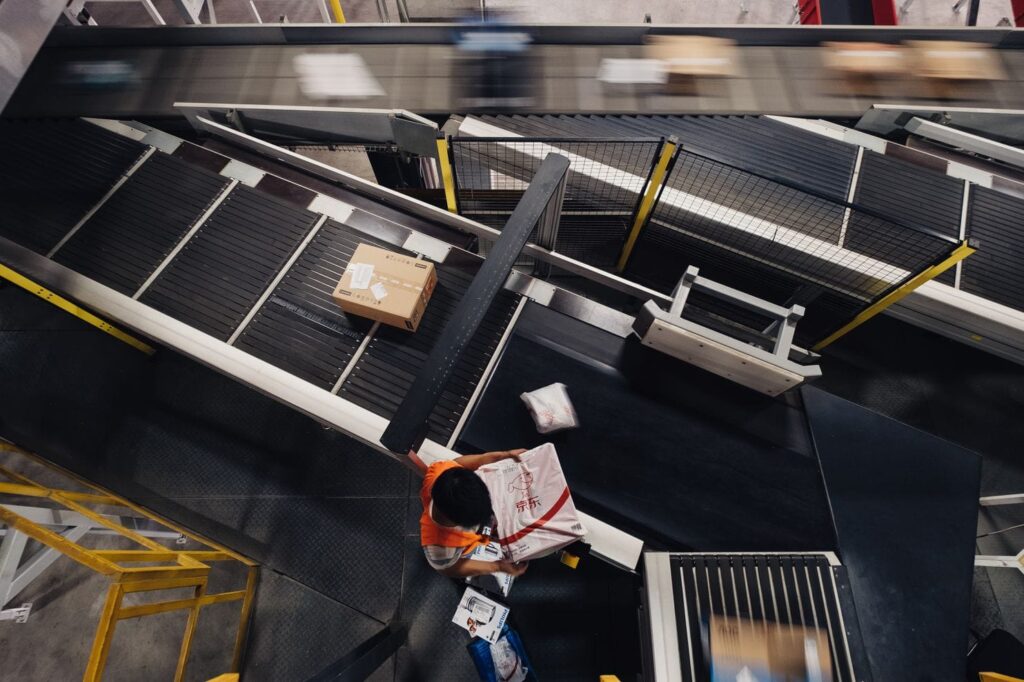

In this model, the user doesn't need to select a specific nearby store, just select the products they're after. In cases where a single warehouse (or store playing that role) does not have the stock to fulfill the complete order, sellers send the goods in batches from the primary warehouse or 'frontline' warehouses, or else the dispatcher will collect the goods from other in-stock warehouses.

Pros and Cons

- Advantages: For users, as long as any store has their desired item in stock, the product is available to them.

- Disadvantages: Inventory management and operations are more complicated for chains with multiple warehouses or stores.

- Challenges: Overall logistical flow and order management, as well as offline pick-up by users, present significant challenges, as detailed below.

Order Splitting

On JD.com it is common for sellers to split large ordersinto multiple deliveries at no extra cost to the consumer. Sellers use this strategy for large orders that contain multiple items sourced from multiple locations. Rather than have the customer wait around for sellers to gather all these goods in one warehouse for packaging into one delivery, the seller sends items directly to the customer from the most convenient warehouse and each arrives as soon as is possible. This is especially important to JD.com, which has made its reputation in no small part on its quick delivery times.

This approach has been a hit with users, who strongly prefer prompt delivery times to sellers delaying orders just to deliver them in a single batch.

In general, this technique is able to save both money and time for the seller. However, it does require the following logistics capabilities:

- Batch tracking: Estimated delivery times, logistics status of the packages, and possibly real-time tracking of each item need to be handled separately for a single order.

- Batch receipt: The full order receipt must be divided per package.

Refund and Return Splitting

When orders are split, sellers should also split refunds and returns. For example, if one package takes too long to arrive, the customer may want to demand a refund for this package alone without refunding the entire order, as they have no issues with the other packages making up that order.

Offline Delivery and Inventory Liquidity

In the mixed inventory model, offline stores do not necessarily have extensive stock on-hand at all times. As such, inventory needs to be liquid in order to facilitate customer pick-up of goods from their local store. You need to check stock against customer orders, and then quickly redirect any out-of-stock items from other stores or warehouses, to ensure the product's availability when the customer wants to pick them up. This can mean significant operational costs and close management in order to achieve good user experience.